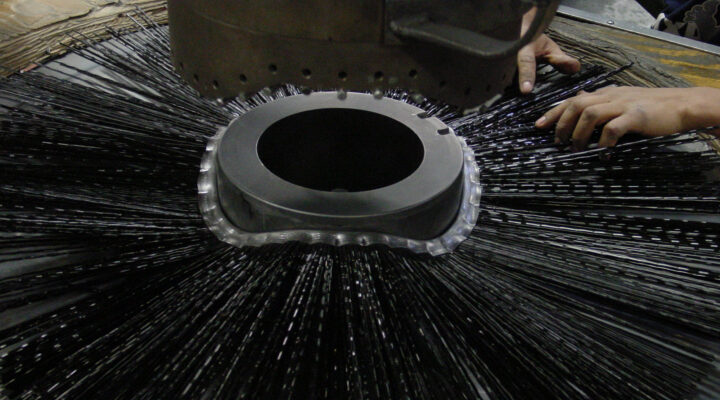

Wafers are used to make main brooms for mechanical sweepers, road construction sweepers, and sweeper attachments.

Wafers are individual broom discs that stack on top of each other on a wafer rack to make a full broom core. There are two style wafers – Convoluted and Flat. Convoluted wafers have a wavy shape and flat wafers are well, flat.

Most people tend to stick with whatever broom type or configuration is on the sweeper when the sweeper is purchased. If you’re using flat wafers you may want to see why switching to convoluted can save you time and money.

Economics of Convoluted vs. Flat Wafers

Compared to their larger cousin, the tube broom, wafers are compact, easy to store, and economical. The downside is that a broom core made of wafers typically gets changed in the shop, not in the field.

Flat wafers require spacers to be placed in between each wafer when building a broom. A spacer is essentially the center ring of the wafer without the bristle.

While you can get creative with the broom configuration, wafers need proper spacing for the bristle to have the correct flicking action to sweep properly. In theory, you could make an entire broom core without any spacers to create a very dense broom. The problem is that the bristle will tangle and there will be no flicking action resulting in poor performance.

Spacers can and should be re-used when possible. They are made of steel so they’re not cheap to replace. Often when making a combo broom, a broom with both poly and wire wafers, the wire gets tangled up as the broom wears. Instead of trying to save the spacers, people tend to slide the wafers and spacers off the rack together and toss them both. This scenario requires the purchase of new spacers when building a new broom each time.

Convoluted wafers on the other hand self-space and do not need spacers. By rotating the convoluted wafer when installing, the high spots on the wafer match up with the low spots on the wafer before it. This process creates a perfectly spaced broom. When it’s time to change the wafer, you simply pull them off and put new ones on.

There is no noticeable difference in the sweeping performance of a broom made with convoluted wafers verse flat wafers. Unless you’re making some type of custom configuration with the flat wafers and spacers, converting over to a convoluted wafer will save you time and money when replacing your broom.