Wafer Brooms

Manufactured to meet the industry’s highest standards, Keystone’s Poly, Wire and Combo Wafers are forerunners in quality and durability. Providing you with more usage hours between broom changeovers, Keystone’s Wafers are ideal for attacking tough road debris such as asphalt, gravel, mill grind, clay and mud. Wafers are an ideal choice for sweeper attachments and road construction brooms. They are easy to change and available in a variety of options.

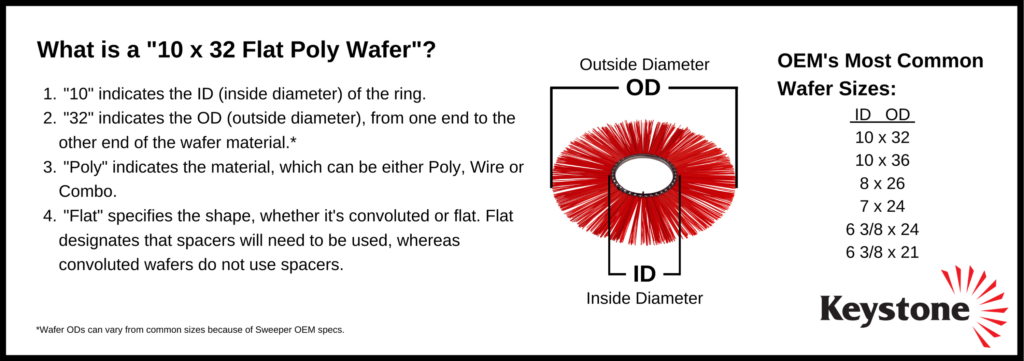

Wafers are available in two styles, convoluted and flat. Flat wafers have a flat ring and typically are stacked with a spacer in between. Convoluted wafers have a wavy ring and align is such a way that they do not have a spacer.

A broom made with wafers can be all poly or a combo poly/wire mix. When choosing a combo broom construction you can alternate a poly wafer and a wire wafer in either a flat or convoluted style. You can also choose the combo poly/wire wafer which has both poly and wire mixed in each wafer.

Understanding a Wafer

Street Sweeping, Road Construction, Tractor Mount Sweepers, Skid Steer Loaders. Wafers are the most common broom for the construction market. Most notable, the front tow behind and tractor mounted attachments.

Flat (1-pin): Steel spacers required to maintain uniform spacing between wafers. Convoluted (2-pin): ‘Spacer less’ installation – ring shaped (waved inner ring) to create it own spacing.

Poly: Normal sweeping, more ‘flick action’. Wire: Aggressive sweeping, more ‘cutting action’. Combo: Poly and wire in one wafer. Provide the combined benefits of both wire and poly wafers. More convenient installation and allows for one inventory.